How to Grade with a Skid Steer

Grading using a skid steer prepares a flat, safe surface or work area ready for many jobs. This tool will enable you to get your worksite ready for projects such building foundations, parking lot construction, or driveway constructing.

Whatever your grading need, a skid steer loader can be the greatest choice available to you. We go over how to grade with a skid steer in this post along with how this building tool stacks against other grading machines.

Why Use a Skid Steer for Grading?

For a few reasons, a skid steer is a smart choice for grading. It comes in several forms to fit diverse terrain, is lightweight and incredibly moveable. Working on dirt calls for a wheeled skid steer; on soft ground, its relative, the track loader, performs better. On ground like muddy dirt, snow, damp surfaces, and gravel, track loaders shine.

Although a skid steer may serve a range of grading uses, it is generally appropriate for small to medium operations. In confined areas, Mini skid steers are perfect. Larger areas—such as grading for major structures, lengthy highways, or railway construction—are ideally suited for bigger vehicles like motor graders or bulldozers.

How to Grade with a Skid Steer

Knowing the kinds of tasks a skid steer performs best for, the following is the process to grade with one.

Step 1: Evaluate the Location and Eliminate Any Barriers

Make sure the space you’re going to grade is free of obstructions and prepared for work beforehand.

Inspect the area for potential hazards, such as subterranean plumbing or sprinkler systems. Check for any obstacles, such as wires or cables, or big rocks. To make sure the location is safe for grading, you should also call 811 before beginning any excavation.

A skeleton bucket attachment for removing big boulders is one skid steer attachment that might be useful in this stage, but we’ll go into more detail about attachments later.

In order to keep everyone informed during the process, be sure to indicate the places where you may and cannot grade or dig.

Step 2: Choose the Right Bucket Attachment

Verify that the bucket attachment you are using fits the machine properly. To prevent the tires from having an adverse effect on the grading job, the bucket should be two inches bigger than the vehicle’s tires, or extend past them by around two inches.

Step 3: Begin Rough Grading

Start with rough grading initially to mold the earth for the intended height and contour whenever you are ready to grade. This entails either adding road bond, gravel, soil, or other materials into the mix and distributing it throughout the area you wish to grade or redistributing dirt or ground as needed.

In order to prevent water from pooling in the ground you are grading, rough grading also aids in determining its slope. If you are grading near a structure, make sure the slope slightly slants away from the foundation to prevent pooling of water around it. Almost any project will need a little slope to prevent water collecting.

Driving over an area to rough grade it will push the ground and run over it with the skid steer to flatten it as necessary.

Step 4: Back Drag to Flatten the Grade

After you have equally distributed the earth or dirt throughout the area you are grading, it is time to back drag the bucket attachment.

Point the bucket attachment down toward the ground and run the machine backwards pulling the bucket attachment in this angle to flatten the region you choose. Another name for this is “float mode,” as the bucket seems to be floating—that is, it sits on the ground free from any pressure. Grading blades from a bucket enable you to shape the area without excavating.

Then you may relax the angle to have the bucket flat when you wish to taper the soil you are dragging. Using the bucket’s cutting edge to match the slope, you should be pulling material from the high points down to the low locations.

Step 5: Spray the Ground with Water and Make Final Adjustments

The last stage in establishing the final grade is to sprinkle the ground with water and search for areas where water pools when you feel like you have the ground ready to fulfill the elevation criteria you require by shaping, contouring, and eliminating clumps and unwelcome bumps.

Knowing where or whether water pools suggests that you might have to keep grading to avoid puddles at another occasion or when it rains. You have a completed grade if you find that water does not pool in your workspace.

Which Attachments for Skid Steer Aid in Leveling the Ground?

To assist with it, you might wish to use a certain skid steer attachment, depending on the task or project you’re working on. These are a few popular attachment types along with their uses.

Buckets: Among the most often used attachments, buckets may scoop, excavate, and move soil, sand, and gravel among other things. Apart from the standard skid steer bucket, there are other specialist choices catered for various jobs and materials, including several that fit well as grader attachments. Tooth buckets for digging at deeper depths or breaking through tougher materials, smooth buckets for producing a better finish, and skeleton buckets for removing and sorting rocks and big trash from soil and sand are a few of them.

Landscape rakes assist to removing trash, including pebbles and grass, from soil surfaces. Their value is particularly great in landscaping projects and ground preparation for sowing or planting.

Levelers—also known as planers—have more aggressive grading capacity. Particularly in landscaping uses, they may assist grade, chop, level, and cultivate ground.

Skid Steer vs. Track Loader: Which One Do I Need?

A skid steer and a track loader vary primarily in design; a skid steer runs on wheels whereas a track loader operates on tracks. Which vehicle you need might depend on elements including terrain, speed, maneuverability, power, cost, and site clean-up requirements.

Use a Skid Steer for Hard Surfaces

Skid steers’ wheels improve traction on hard or compact terrain. They are more suitable for work on surfaces like pavement, Concrete; Soil, For leveling dirt and soil, skid steers are also perfect. On muddy or damp ground, however, track loaders usually offer better traction.

Choose a Track Loader for Uneven, Soft Terrain

Track loaders perform best on uneven, soft ground, such as muck dirt, as was already noted. Snow-wet surfaces Sand Grasp Gravel Using a track loader rather than a skid steer reduces the possibility of damaging soft ground or vegetation.

Speed Through Your Project with a Skid Steer

Particularly on flatter ground, skid steers travel quicker than track loaders since they are on wheels. They may also negotiate to turn more precisely in confined areas. For traveling back and forth over a space you need leveled, track loaders are more suited.

Access More Power with a Track Loader

Because track loaders distribute their weight more evenly, they can raise greater weight without slippage. They can also more gently compress the earth. Skid steers are lighter weight, hence moving larger stuff might be challenging.

Save Money with a Skid Steer

Renting a skid steer loader usually pays less than renting a track loader. Cost shouldn’t be your main deciding factor, particularly if your project asks for a certain sort of terrain that works better for one or the other—you will want to select the appropriate one for your project demands. If both are good choices, however, renting a skid steer might run you a bit less.

For what other machines can grade land?

Although there are other earthmoving choices you should take into account, skid steers are excellent graders. Here are some more grading-related varieties of tools:

Motor Grader: When you want exact grading, a motor grader is a great choice. For roadwork, mining, constructing foundations, and ditching, it performs admisitely. This dual-purpose equipment may also travel between road-based job sites.

Bulldozer: When you need to level soil for vast areas—roads, buildings, landscapes, and railroads—that calls for less accuracy—bulldozers are a fantastic choice.

Wheel Tractor Scraper: Particularly on wet ground, wheel tractor scraper is a versatile tool best utilized for leveling, gathering, dumping, or moving items. Should you not have access to a dump truck, this is a reasonable alternative.

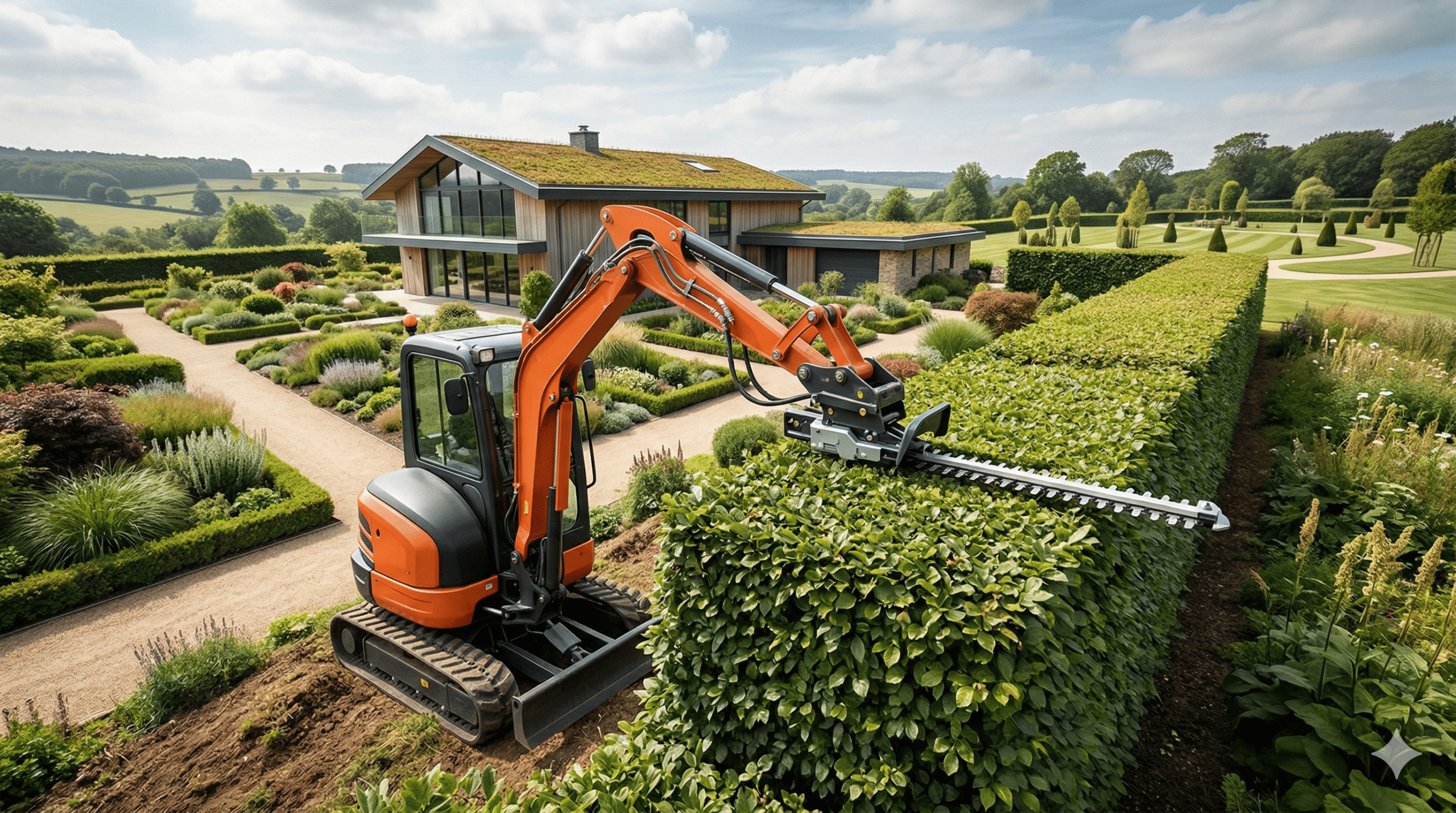

Excavator: An excavator fit for heavy-duty earthmoving operations may dig to considerable depths. Its tilt swing allows you backfill ditches and level different types of terrain as well as the leverage to shape contours and build slopes while grading. The more compact form, also known as a tiny excavator, would be used for smaller jobs.

Ready to Grade?

A good task depends on appropriate tools. For many grade and earthwork requirements, skid steers are a great alternative. Look at track loaders or other graders if you want something somewhat more specialized.

MACHINERY ONLINE has all your equipment needs covered whether your ready to buy a skid steer or another earthmoving machine.