What Are Excavator Working Principles In 2024

Unveiling Excavator Working Principles in 2024

Anyone engaged in civil engineering, construction, or heavy machinery has to grasp the excavator working principles. Modern building sites mostly rely on excavators since their unequaled adaptability and efficiency. We investigate the development, parts, and operating ideas of excavators in 2024 in this all-inclusive manual. Prepare to learn about the most recent technical developments and find out how these strong machines might transform your work.

Introduction to the Evolution of Excavators in 2024

Since its introduction, excavators have advanced a great distance From crude steam-powered tools to modern hydraulic systems, excavators’ development is evidence of human creativity. Excavators will be more powerful, flexible, and efficient in 2024 than they have ever been. They are indispensable on building projects all around as they include modern technologies.

The main parts and operating ideas of contemporary excavators will be taken you through in this blog article. Along with the most recent technological developments, several kinds of excavators, and actual case studies of their uses, you will also learn By the end, you will value these amazing tools more highly and see how they will shape building going forward.

Overview of Key Components and Working Principles of Modern Excavators

To understand how excavators work, we must first familiarize ourselves with their key components. Modern excavators consist of several essential parts, each contributing to their overall functionality and efficiency.

The Engine and Hydraulic System

Most excavators have diesel engines, which provide the horsepower required to tackle different job levels. The engine generates the movement of several components by running a strong hydraulic pump that pushes oil through the hydraulic system. Hoses, cylinders, and valves regulating oil flow and excavator part movement comprise this system.

Using a set of controls, the operator controls the movement of these parts, therefore facilitating effective material handling and digging. Understanding the engine and hydraulic system helps one to grasp the force and accuracy behind contemporary excavators.

The Excavator Arm

Digging and material reaching are mostly dependent on the excavator arm, sometimes known as the boom. It comprises the main boom, stick, and bucket among numerous pieces. The major length comes from the main boom; the stick gives extra reach. Materials are dug and scooped from the bucket, which is hooked to the stick.

By means of hydraulic cylinders, operators regulate the arm’s movement, therefore facilitating exact and effective functioning. The excavator arm’s design and operation make it a flexible instrument for many kinds of building work.

Tracks of Excavator

The excavator gains motion and stability from tracks, sometimes referred to as the undercarriage. Comprising metal plates joined by pins and bushings, the tracks let the machine operate over a range of terrain and under demanding conditions. The sprockets at the rear of the machine, driving the rails, are run by hydraulic motors.

By means of foot pedals, operators control the track movement, therefore allowing them to vary the speed and direction of the excavation. The design of the tracks guarantees stability and traction, which are necessary for working on soft ground, pebbles, and hills.

The Latest Technological Advancements in Excavator Design and Operation

The construction industry is witnessing rapid advancements in excavator technology. These innovations enhance performance, safety, and efficiency, making modern excavators more powerful and user-friendly.

Advanced Control Systems

Integration of sophisticated control systems is among the most important developments in excavator technology. By means of sensors and software, these systems offer real-time data, thereby allowing operators to make exact motions and maximize performance. Features including telematics, automated grading, and GPS direction help to increase accuracy and efficiency on the job site.

Hybrid and Electric Excavators

Growing focus on sustainability is driving hybrid and electric excavators’ appeal. These environmentally efficient substitutes for conventional diesel-powered excavators cut fuel usage and pollution, therefore benefiting the surroundings. While completely electric excavators provide zero-emission running, hybrid systems mix electric motors with diesel engines to maximize fuel economy.

Enhanced Safety Features

In the building sector, safety comes first, hence, modern excavators include sophisticated safety measures to guard workers and operators. These cover autonomous stop systems, collision detection systems, and 360-degree cameras. These characteristics guarantee a safer workplace by improving visibility and lowering the accident risk.

Safety Features in Excavators

Safety features are integral to modern excavators, ensuring the well-being of operators and nearby personnel. Below are the key safety features that have become standard in excavator design:

- Stability Systems: These systems utilize counterweights and advanced sensors to monitor the machine’s position, preventing tipping during operation and maintaining optimal balance while digging or lifting heavy loads.

- Operator Safety Cabin: The cabin is constructed from reinforced materials designed to protect operators from falling debris. It is also designed to provide a clear, unobstructed view of the work area, enhancing situational awareness.

- Enhanced Visibility: Equipped with large windows and strategically positioned mirrors, excavators significantly reduce blind spots, allowing operators to maintain awareness of their surroundings and enhance overall safety.

- Advanced Communication Systems: These systems alert operators to potential hazards through auditory alarms and visual indicators, signifying when the machine approaches unsafe operational limits.

- Automatic Shut-off Systems: These systems ensure the excavator automatically shuts down if it becomes overloaded or operates outside of safe parameters, mitigating the risk of accidents.

- Emergency Stop Controls: Easily accessible emergency stop controls enable operators to quickly halt all functions of the excavator in case of an emergency, minimizing potential harm.

- Obstruction Detection Systems: Incorporating proximity sensors and cameras, these systems detect obstacles around the excavator, alerting the operator and reducing the risk of collisions.

- These safety features help comply with industry regulations, foster a safer working environment, enhance productivity, and build confidence among operators and crew members.

- As the construction industry evolves, prioritizing innovative safety technologies in excavator design and operation will remain essential.

By integrating these safety features, modern excavators not only comply with industry regulations but also enhance productivity while fostering a safer working environment for all involved.

How Excavators Are Used in Various Construction Projects

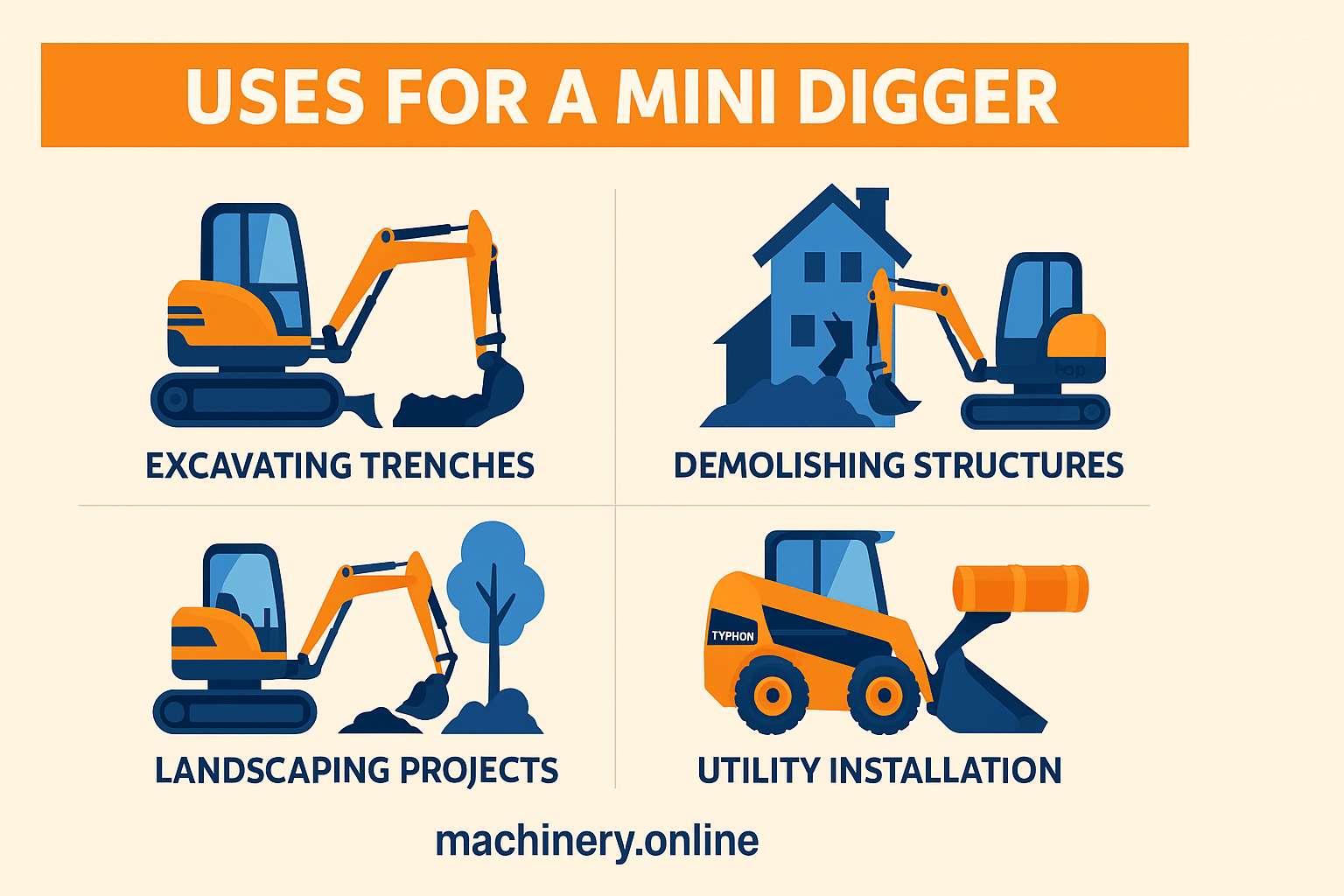

Excavators are indispensable tools on construction sites, offering versatility and efficiency in various tasks. Their applications range from digging foundations to demolishing structures, making them essential for many projects.

Foundation and Trenching

Excavators are commonly used for digging foundations and trenches. Their powerful hydraulic systems enable precise excavation, ensuring stable and level foundations for buildings. Whether it’s a residential or commercial project, excavators play a crucial role in laying the groundwork.

Demolition

Excavators fitted with specific attachments can quickly destroy buildings in demolition projects. Shears, hydraulic breakers, and grapples let for controlled demolition, therefore reducing damage to neighboring areas. The adaptability and force of excavators make them perfect for precisely and quickly demolishing structures.

Material Handling

Excavators are also used for material handling, such as loading trucks and transporting heavy objects. Their ability to reach and lift materials with precision makes them valuable in construction logistics. By efficiently moving materials, excavators contribute to the smooth progress of construction projects.

What and How Powered an Excavator?

Understanding how excavators are powered is critical to appreciating their capabilities. Most modern excavators rely on diesel engines and sophisticated hydraulic systems to complete their tasks efficiently.

Diesel Engines

Diesel engines power the majority of excavators, providing the necessary horsepower to handle various workloads. These engines are designed for durability and efficiency, allowing the machine to operate in demanding conditions.

Hydraulic Systems

The hydraulic system is responsible for converting the energy from the engine into the movement of the excavator’s components. It consists of hoses, cylinders, and valves that control the flow of oil, enabling precise and powerful movements. The operator uses controls to manipulate the hydraulic system, ensuring efficient digging and material handling.

The Excavator’s Arm

The excavator arm, also known as the boom, is a critical component responsible for digging and reaching materials. It consists of several sections, each playing a vital role in the arm’s functionality.

Main Boom

The main boom is the largest section of the excavator arm, providing the primary length. It is connected to the base of the machine and serves as the foundation for the other sections.

Stick

The stick, affixed to the top of the main boom, provides additional reach for the excavator’s arm. It allows the operator to extend or retract the arm, increasing its versatility.

Bucket

At the end of the stick is the bucket, used for digging and scooping up materials. The bucket is attached to the stick with a hinge, enabling it to move up and down. Operators use controls to manipulate the movement of the arm, ensuring precise and efficient operation.

Tracks of Excavator

Tracks, also known as the undercarriage, provide the excavator with mobility and stability. They are essential for moving the machine across various terrains and working in challenging conditions.

Composition and Function

Metal plates connected by pins and bushings make up an excavator’s tracks. These plates provide stability and traction, allowing the machine to operate on soft soil, rocks, and slopes.

Hydraulic Motors

Hydraulic motors drive the sprockets at the rear of the machine, powering the tracks. Operators use foot pedals to control the movement of the tracks, enabling them to change the excavator’s speed and orientation.

Terrain Adaptability

The tracks’ design ensures stability and traction on different terrains, including soft soil, rocks, and slopes. They can also be adjusted to provide different levels of ground pressure, essential when working on delicate surfaces.

Difference Between Different Excavator Working Principles

While all excavators operate on the same basic principle—the hydraulic system—there are different types of excavators, each with unique working principles.

Standard Excavator

The standard excavator is the most common type, using a boom, stick, and bucket for digging and moving materials. Operators control the equipment using hydraulic handles and pedals while seated in a cab.

Long-Reach Excavator

The long-reach excavator is designed for working in areas that are difficult to reach. It has an extended arm and boom, allowing it to reach further than a standard excavator. This type is commonly used for dredging and clearing out bodies of water.

Mini Excavator

The mini excavator is a smaller version of the standard excavator, designed for tight spaces. Its compact design and smaller bucket make it ideal for digging in small areas such as backyards and gardens.

Case Studies and Real-World Examples of Excavators in Action

Excavators have proven their worth in various real-world applications. Here are some examples of how these machines have been used in different construction projects.

Urban Development

In urban development projects, excavators are used for digging foundations, trenching, and material handling. Their versatility and efficiency make them indispensable for constructing residential and commercial buildings.

Infrastructure Projects

Excavators play a crucial role in infrastructure projects such as road construction, bridge building, and pipeline installation. Their ability to handle heavy materials and perform precise excavation ensures the smooth progress of these large-scale projects.

Environmental Restoration

Excavators are also used in environmental restoration projects, such as wetland rehabilitation and riverbank stabilization. Their ability to work in challenging conditions makes them ideal for restoring natural habitats.

Future Trends and Innovations in Excavator Technology

The future of excavator technology promises even more advancements, enhancing performance, safety, and sustainability.

Autonomous Excavators

Autonomous excavators, equipped with AI and machine learning, will revolutionize the construction industry. These machines can perform tasks without human intervention, increasing efficiency and reducing the risk of accidents.

Remote Control Operation

Remote control operation allows operators to control excavators from a distance, improving safety and precision. This technology is particularly useful in hazardous environments where human presence is risky.

Sustainable Excavator Solutions

Sustainability is a growing concern, and the construction industry is adopting eco-friendly solutions. Hybrid and electric excavators reduce emissions and fuel consumption, contributing to a greener future.

Conclusion and the Importance of Understanding Excavator Working Principles

For civil engineers, machinery aficionados, and construction workers, knowledge of excavator functioning principles is vital. Understanding the parts, technology, and uses of these machines helps one to value their possibilities.

Offering efficiency, adaptability, and power, excavators are absolutely essential in the building sector. These tools will become even more essential as technology develops, helping to shape building going forward.

Use our blog to remain in touch and learn more about excavator technology and find the newest developments. Your next building project would greatly benefit from the knowledge and ideas offered here.