Mastering the Mini Excavator Craft Without Breaking a Sweat

Introduction

Mini excavators have become quite important instruments in the contemporary landscape and building environment. Among landscapers, builders, and do-it-yourselfers, their adaptability, small scale, and great power have made them a preferred option. Whether you’re excavating foundations, managing demolition projects, or creating a garden paradise, knowing the small excavator will improve your ability to be efficient and skilled to unprecedented degrees.

This blog article is meant to walk you through basic mini excavator operation guidelines so you may properly and safely maximize their potential. By the conclusion of this book, you will have acquired useful knowledge ranging from the principles of these powerful computers to pragmatic uses highlighting their capability. Let’s uncover the secrets of effective mini excavator operating together and ensure every project succeeds!

Understanding Mini Excavators

Often called tiny, more nimble versions of their bigger counterparts, mini excavators—also known as compact excavators—have Their capacity to function in limited areas without compromising power distinguishes them. Usually weighing one to five tons, these machines are perfect for jobs needing accuracy without a heavy-duty footprint.

Key parts of a small excavator include its undercarriage, boom, stick, bucket, and operator’s cab. Every component is rather important for its functioning. Whereas the boom and stick provide for a great range of motion, the undercarriage offers stability and maneuverability. The workhorse, flexible for grading, trenching, or excavating, is the bucket.

Mini and bigger excavators vary in size, cost, and application even if their functionality is same. Often more affordable and with unparalleled mobility, mini excavators are the preferred choice for smaller jobs. Knowing these differences guarantees efficiency and effectiveness by helping operators choose the correct machine for the correct task.

Mini Excavator Operating Basics

Run a small excavator effectively only if you are committed to safety. Safety should always come first, hence it is essential to observe accepted rules. Start with donning suitable PPE like steel-toed boots, safety vests, and hard helmets. Before every usage, carefully examine the excavator to look for any obvious damage or leaks that can endanger safety.

Likewise important is getting the workspace ready. Remove any possible risks and clear the ground to provide sufficient stability for the weight of the machine. List the subterranean utilities to avoid unintentional harm. Apart from improving safety, a well-prepared work environment opens the path for a seamless and effective operation.

Familiarize yourself with the controls of the little excavator before you begin excavating. Standard joystick controls for the boom, stick, and bucket motions run most machines. Spend some time honing in an open space to feel the responsiveness of the controls. Precision and efficiency in doing real activities depend on developing muscle memory for the controls.

Tips for Efficient Mini Excavator Operation

Understanding how to utilize your mini excavator’s arm and bucket will help you to optimize its efficiency. Extend the boom, then coil the bucket to scoop up the dirt for digging chores using the teeth on it. To grade, level the ground using the bottom edge of the bucket. Learning these methods guarantees that every action has intent and efficiency.

Tight space maneuvering calls both accuracy and grace. Keep the boom and stick near the machine while negotiating limited spaces to reduce the possibility of running into objects. Move gently and under control to prevent abrupt changes that can cause the excavator to tilt. Practicing in confined areas helps you to confidently perform difficult moves.

Maintaining optimal performance of your mini excavator depends on regular maintenance. Create a regular maintenance program including hydraulic line inspections, fluid level checks, pivot point greassing. Timeful maintenance guarantees best performance throughout the machine’s lifetime by preventing malfunctions and extending its lifespan.

Real-World Applications

Mini excavators’ adaptability and value have made them useful in many real-world uses. On building projects, they shine in jobs like site preparation, foundation excavation, and utility trenching. Their small scale makes them perfect for urban building projects as it lets them access places where bigger machinery cannot reach.

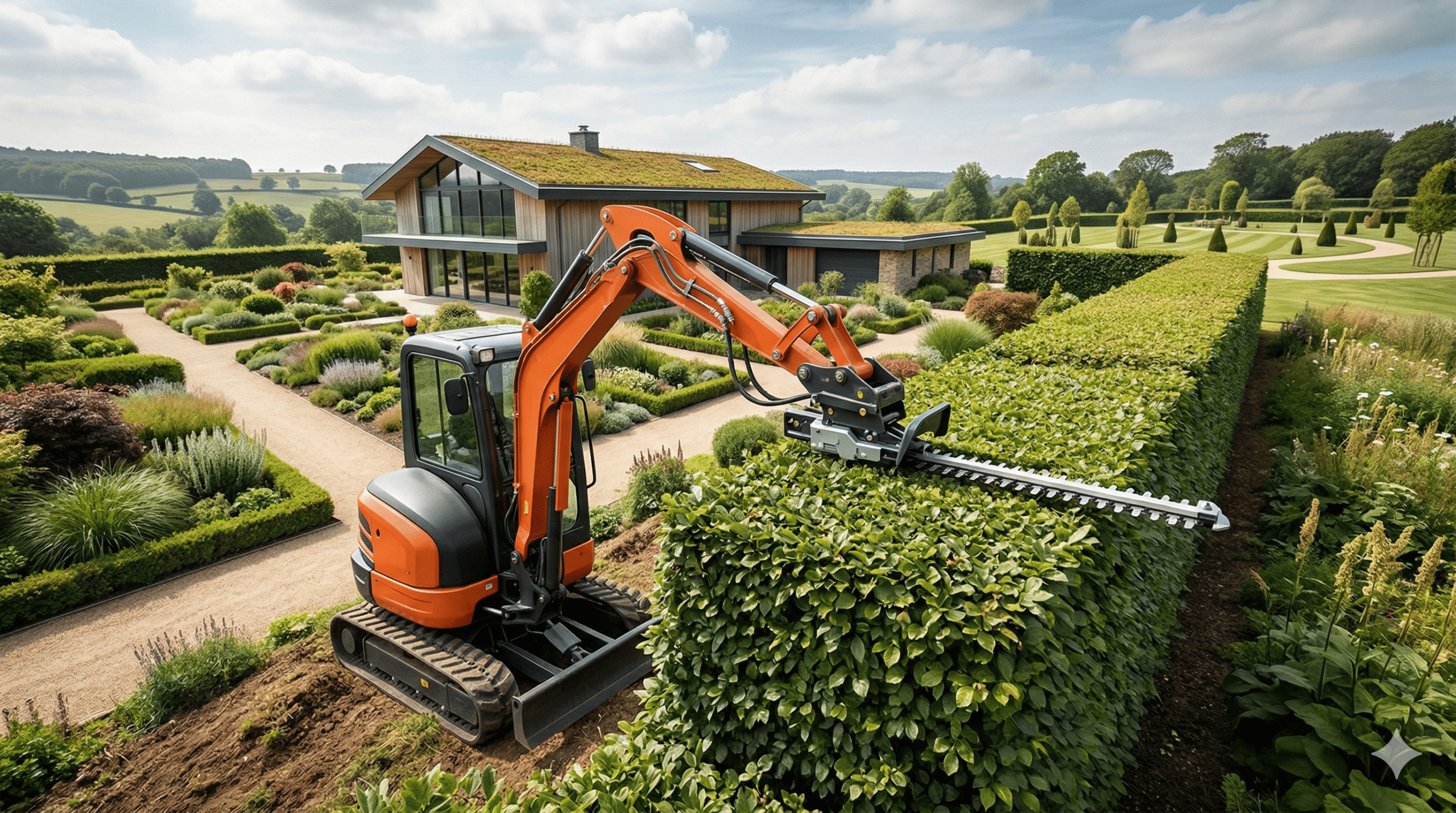

Mini excavators help significantly with landscaping jobs. Whether you’re constructing garden beds, a retaining wall, or irrigation systems, these machines provide the accuracy and force required for complex work. One major benefit is their capacity to do sensitive chores without generating too much disturbance of the surroundings.

Let’s review a few example studies illustrating effective small excavation operation. One project saw a crew easily maneuvering around existing buildings using a small excavator to dig a backyard pool. In another instance, a landscaping business used the grading features of the mini excavator to create a tiered garden from a hillside. These illustrations show the machine’s flexibility and efficiency in many kinds of jobs.

Topics Covered:

- An Introduction on Mini Excavators

- Operating a Mini Excavator, Best Practices for Mini Excavator Operation vs. Standard Excavators

- See Quinn Company for Your Mini Excavator Needs.

- A Mini Excavator: An Overview

Often used in operations connected to construction, a tiny excavator is a multifarious tool. It is lighter and more portable than a conventional excavator, thus easily completing a range of vital jobs. Usually, mini excavators have many main components:

- The operator of the mini excavator sits within the cab.

- Engine: Runs the small excavator so the operator may use hydraulic tracks to control the boom and travel.

- House: fits the tiny excavator’s hydraulic cylinders, engine, and cab underline. It is positioned on a hinge above the undercarriage therefore enabling a complete 360-degree rotation.

- Undercarriage: The small excavator attached to the home has a foundation. It maintains the weight of the machine and features the engine, gears, and track roller allowing the small excavator to run.

- Stick: Long hydraulic arm with many attachments including blades, thumb, trenching buckets, and grapples. The stick connects the boom.

- Attached to the undercarriage of a compact excavator, this blade grades and may be positioned front or rear of the machine to provide stability when digging.

Mini excavators come in a range of weights and sizes that let you choose the ideal tool for your job. Should your budget be strained by a small excavator purchase, think about renting one. Forty to fifty percent of the mini excavator market are rentals, which guarantees that you will discover the correct model for your requirements.

Operating a Mini Excavator – Comprehensive Guide

View Our Mini Excavator Selection for Sale Here

Mini Excavators vs. Standard Excavators

How do mini excavators differ from standard excavators? Here are a few ways:

- True to its name, mini excavators are smaller and lighter than conventional excavators. Right now, the market for small excavators consists of 10-ton or smaller equipment.

- Mini excavators may have a variety of attachments that increase their use.

- Mini excavators have a less environmental effect as they are lightweight. Their less obvious track markings help to minimize harm to plants and soil.

- Mini excavators’ small scale lets them fit into confined areas on increasingly populated sites. They may be conveniently hidden in corners without interfering with other tools.

- Mini excavators are often more maneuverable, particularly when negotiating other objects and vehicles. They can go over crammed lots with ease.

- Mini excavators’ low weight makes loading onto trucks and moving between work sites simple. A conventional excavator would be too hefty for a trailer or utility vehicle, but a tiny excavator might fit very well.

Operating a Mini Excavator

Here’s how you can get started with a mini excavator:

- Lower the blade using the control lever until the machine is just marginally raised.

- Use the throttle for power: Until you feel more at ease, if you are new at running a mini excavator, think about running at half power.

- To start digging, press the main stick to extend it outward. Then position the stick and bucket. Use the bucket control to slant the

- bucket when the stick is about halfway extended. Lower the boom until the teeth of the bucket hit the ground. As necessary, use the joysticks to hone your angle.

- Dig using the stick. Pull the stick to ground-sink the bucket. Pull the main boom lever then to keep your grade. Should you have a swing or variable-angle boom, you may rotate the boom to empty the soil. Alternately, turn the little excavator to move the soil to the designated dumping point.

Mini excavators’ lightweight design and wide selection of attachments make them multipurpose enough for use on a variety of job sites. Here are a few different uses for mini excavators:

- Digging Holes

Because of their diverse attachment choices and capacity to negotiate difficult-to-reach areas, mini excavators are remarkable diggers. While digging with a small excavator is efficient and quick, old-fashioned shoveling is time-consuming and tiresizing.

- Landscaping

Mini excavators dramatically save labor and speed up landscaping chores. Using a tiny excavator can help you dig for irrigation ditches or for planting plants and bushes instead of hand shoveling soil. Additionally able to navigate the site without leaving significant track traces or injuring soil or plants is a lightweight compact excavator.

- Demolishing Structures

Additionally useful for demolition are small excavators. Although they are not fit for destroying big buildings, many building projects call for breaking down smaller constructions like sheds. Comparatively to hand-powered equipment, mini excavators provide efficiency and safety; their small size helps them to negotiate narrow areas on the construction site and gates.

- Installing Outdoor Structures

Mini excavators may be very helpful when building projects like hot tubs and pools that need for extensive excavation. Although manual shoveling would be a time-consuming, exhausting chore, a tiny excavator can do the work easily. Moreover, it won’t contaminate the nearby soil or become caught while attempting to access the excavation site.

How to Operate a Mini Excavator Effectively

Knowing the right approach to operate your mini excavator can help you derive the best performance from it. Here are a few tips:

- Read the Instruction Manual

The operator’s handbook has priceless knowledge about running a little excavator. It offers guidance on the operation of every control, the placements of fire extinguishers and warning labels, and the circumstances under which the machine should or should not be used. Make sure you grasp the fundamental principles of the functioning of the mini excavator, even if you do not study it cover to cover.

- Inspect the Machine Before Use

Before you start operating your small excavator, develop the habit of closely examining it. Search for leaks of fluid or loose hoses that can compromise your machine’s operation. Check the coolant, lube, and oil levels; furthermore, look for damage in the tracks.

- Test the Mini Excavator

Testing your small excavator will help you to become acquainted with its running characteristics before using it for the first time. Different models have different layouts, hence, the new mini excavator may not run precisely like the one you had used. Test the machine in an open, big, flat space free of obstacles. Try all the controls, then work on spinning the cab and moving the boom.

- Practice Driving on Tracks

Most micro excavators run on rubber tracks, which differ in handling from wheeled axles. To help turn, the left and right tracks may even travel separately. If you have never driven a small excavator, practice to learn how the tracks respond to the terrain and controls.

- Ensure Correct Balance

Especially with smaller machinery, your mini excavator could flip over if you improperly balance its weight. Extended or retracting the stick will help you balance your tiny excavator.

Conclusion

Learning the craft of mini excavator operating will change your attitude to gardening and building jobs. Understanding the principles, giving safety first priority, and using effective methods will help you to fully use these flexible equipment. Recall that becoming a competent operator is closely related with experience and practice.

Please provide your own advice and experiences in the space for comments below. Interacting with other aficionados may provide operators insightful analysis and help them to feel a community. Please get in touch if you have additional queries or like to investigate more about small excavators.

Mini excavators are very revolutionary in the fields of gardening and building. Equipped with the information and tools required to maximize their potential, see how successful your initiatives become!

Starting building projects with tight deadlines and rigorous standards for quality calls for a strategy to maximize output without compromising the health of your staff. Essential is a compact, agile tool that can negotiate uneven ground, fit through small passageways, and spin without damaging nearby buildings or equipment.

Often the perfect answer are little excavators. These machines provide great agility and less collateral damage in addition to the efficiency you need to quickly complete jobs. We will walk you through handling a small excavator in this article and go over the many advantages of these equipment for various applications.