Skid Steer Grapples: Your All-in-One Solution for Material Handling

Skid Steer Grapples

Are you in quest of a multifunctional way to level up your material handling game? Skid steer grapples are the all-around utility attachments that are capable of transforming your current workflow. A skid steer grapple is a powerful tool designed for efficiently moving various materials such as brush, logs, rocks, and construction debris with accuracy and maximum control. If you have to deal with any of the following:

- Landscaping tasks that need brush to be gone

- Sites of construction requiring debris management

- Forestry enterprises doing log handling

- Agricultural assignments where heavy materials are shifted

Then we know the situation. Choosing the right grapple can be more than a bit daunting. So, we have brought you a full 2025 guide to address the matter:

- The different types of grapples and their respective usage cases

- The main features you should look at before buying

- The honest reviews of real users who share their own experience

- The tricks and techniques used by experienced professionals to optimize their time and efficiency

Are you willing to explore the ways the skid steer grapple can enable you to run your organization seamlessly? Let’s get started.

Key Takeaways:

- Skid steer grapples are heavy-duty attachments designed for handling diverse materials, from brush and logs to rocks and construction debris, offering exceptional adaptability.

- They are the go-to solution on numerous landscaping, construction, forestry, and agricultural applications, enabling you to easily finish high impact workloads quickly.

- With the use of a hydraulic system, you can have more precise control and a wider opening angle, thus ensuring the most effective handling – heavy loads and any shape or size of objects are no issue with the system at hand.

- There is a variety of grapples available (root grapple, rock grapple, and versatile grapple attachments) to be fitted according to the specific job needs.

- As you select the skid steer hydraulic grapple, consider the hydraulic power of the skid steer loader, the lift capacity, and the major use of the equipment.

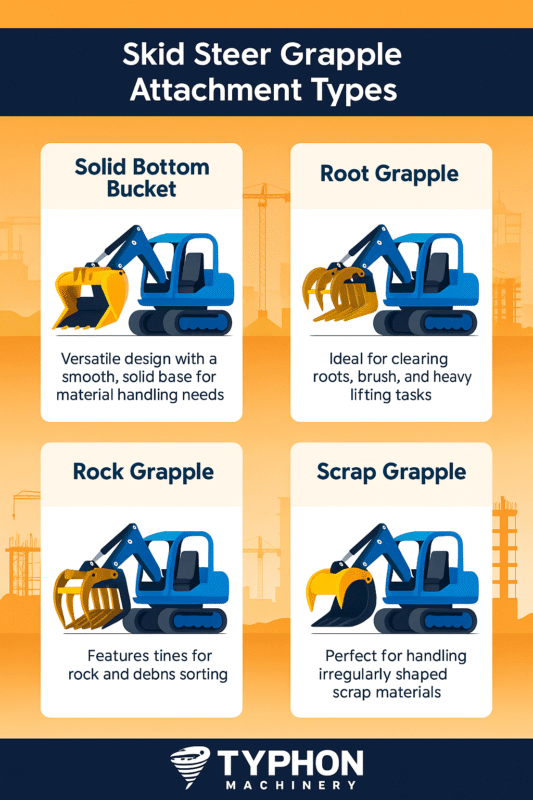

Grapple Attachment Types

Root and Brush Grapples

The root grapple is mainly designed to lift and move organic matter such as brushes, logs, and tree roots. The tines of these accessories are widely separated which ensure that particles of dirt and debris can go through while at the same time they can firmly hold materials of a bigger size. Their rugged construction is ideal for applications including land clearance, forestry work, and agriculture.

Rock and Construction Grapples

Usually, the rock grapple is designed with more closely spaced tines and more sturdy construction to carry out the strenuous task of moving heavy materials. Theses grapples have great performance when it comes to lifting rocks, concrete pieces, and debris from construction site. Their design is focused on giving the most durability and maximum grip strength, so they are suitable for building sites and demolition projects.

Multi-Purpose Grapples

From time to time, a multi-purpose grapple can be referred to as a wicked grapple by those in the industry. What these versatile devices do is, they take the best features of both the root and rock grapples and combine them to make multi-topic tools. Adjusting tine spacing and increased clamping force will allow operators to efficiently deal with various materials. Transporting pallets, cleaning up brush, or managing construction waste, indoor and outdoor use, these multi-use cogwheels are economically efficient.

The versatile design usually consists of:

- Adjustment of the hydraulic pressure with different materials allowed

- The pivot points were sturdy for the durability to be extended

- The distance between the tines was chosen optimally to serve the various applications

- That was the construction of steel that could deliver a heavy-duty performance

💡 Key Takeaway: Grapple types vary with the task where the root grapples fit organic materials, the rock grapples work with heavy debris, and the multi-purpose grapple stands out for flexible usage in a wide range of applications.

Key Features and Specifications

Hydraulic System Components

The core of a skid steer grapple is its solid hydraulic system. These devices rely on hydraulic energy to engage or disengage the grapples and also to deliver a reliable and efficient grip. The most commonly used for such systems is a pressure range of 17 MPa, ensuring a high level of performance in all processes of material handling.

The technical characteristics of modern grapple attachments come with hydraulic cylinders that are able to work within 2 directions and the maximum 3 inches of the rod makes it. A very useful mechanism which simulates the movements of the hand is found in all parts. This type of grapple is suitable for dealing with different tasks due to the wide range of operation.

Design and Construction

The attachments for the skid steer are made of the highest quality materials that have the strength to withstand the toughest job situations. An unobtrusive and sturdy construction where the hydraulic system is mounted inside the frame and the lines are protected and the points are reinforced to avoid any possible damage during the operation process.

The teeth and the separate parts of the fingers are positioned strategically for maximum possible grip while the frame design is responsible for the right distribution of the weight of the attachment. This reminds us that the operator is still able to see clearly during work and thus safety and efficiency are increased on the construction site.

The construction of the attachment also ensures that reengineered pivot points and the bushes will engage without any conflict with the hydraulic system. They play the leading role in a well-coordinated and trouble-free performance of the system. To top it all these parts are of the highest quality and take the load of the device under the most severe circumstances and at the same time, the maintenance need is kept to a minimum.

💡 Key Takeaway: Skid steer grapples are actually hydraulic systems converted into an act of strength through the proper choice of materials and construction; they have an 88-degree wide opening angle and the enclosed parts always available for use on any kind of material handling application.

Picking the Best Grapple

Dimensions and Compatibility

Size and compatibility are the two most essential considerations when choosing a skid steer for material handling. It is essential that the grapple matches the specification of the machine to ensure satisfactory performance. Before you decide, take into account the hydraulic flow rate, the operational capacity, and the physical dimensions of your skid steer.

With an efficiently applied grapple, you will notice a significant increase in productivity as well as the least load on the machine. A standard loader can give the impression of being enough and yet the use of different grapple types can substantially change this condition in favor of the material handing task.

Connection Systems

The functionality of the grapple is based on the connection system of the grappling device. Almost all modern skid steers are equipped with a universal quick-attach system or brand-specific mountings. This common setting makes the transition from one grapple to another and from one tool to another much easier and less time-consuming.

When determining whether the attachment systems work, you should bear in mind the following:

- Hydraulic coupling compatibility

- Quick-connect features

- Mounting plate specifications

- Pin-on versus quick-attach options

The correct attachment system will not only match your skid steer but also ensure a smooth and rapid transition from one job to another.

The versatility feature is especially useful in businesses where different tools are needed throughout the day.

Make sure you have a grip that meets your machine’s hydraulic requirements. This can be confirmed by, among others, checking the flow rate as well as the pressure of your machine to be sure that they are in line with the grip’s specifications and, therefore, the required work can take place.

💡 Key Takeaway: Use a grapple that suits your skid steer’s specifications, taking into consideration its size, compatibility, and ease of attachment to perform material handling activities with the highest possible efficiency and speed.

Last Thoughts

Skid steer grapples are essential for effective and profitable material handling, offering exceptional uniqueness and accuracy for diverse tasks.

These attachments are essential for any construction or landscaping project and have consistently proved successful. Choosing a grapple that meets your individual demands is key to maximizing your investment. Important factors to consider while choosing include hydraulic power, maximum opening angle, and total width.

Choose a grapple that match the capabilities of your skid steer loader, such as a root grapple, rock grapple, or multi-purpose grapple attachment. Improve your material handling efficiency by using our recommended grapple attachments and connecting with reliable vendors. We offer a flawless skid steer solution, with greater productivity and flexibility for your hardest operations. Share your grappling wins in the comments below. We’d love to hear them!

FAQs

What is the average life for a skid steer grapple attachment?

A skid steer grapple that is of good quality and receives proper maintenance and care can serve for 5-7 years or even longer. The useful life of a grapple is mainly reliant on such things as usage frequency, the frequency of maintenance, and working conditions. Much of the equipment’s service life comes from inspecting the hydraulic parts and the teeth regularly.

Can a skid steer grapple get the snow out?

Actually, skid steer grapples are rather productive when it comes to removing snow, particularly when they are handling large ice particles and chunks of snow that have gotten compacted. Namely, the hydraulic system and accurate control are the key features that make the task quick and efficient, although tools that designed specifically for snow could give the best results if the snow management is regular.

What weight figure can a typical skid steer grapple shift?

Under normal circumstances, a common skid steer grapple has the capability of between 3,000 and 6,000 pounds, taking into account the type of model and the mode of construction. At the same time, keep in mind that the real lifting capacity is governed by the specifications of your loader and the hydraulic power that is made available to it.

Are skid steer grapples suitable for compact tractors?

Quite a number of skid steer grapples come with the standard SSQA brackets, so they can be easily used with compact tractors. However, it is of paramount importance to confirm the hydraulic system and quick attach bracket compatibility with the tractor before the purchase is made.

How often should I take care of the hydraulic system of my grapple attachment?

The hydraulic system of your grapple attachment should be serviced every 100-200 operating hours to maintain its condition. This will include checking the oil level, looking for worn hoses, it’s vital to adjust the pressure properly, and also check for the damaged flat faced hydraulic couplers and should they be found with any issue, get them replaced.

Is there any particular reason why a root grapple is different from a standard grapple bucket?

Speaking of root grapple, it is made with more space between the tines intended for dealing with branches, roots, and vegetation; while a standard grapple bucket is designed with tine spacing closer that is best fit to handle demolition debris and varied objects. The root grapple, especially, often comes up with the widest opening for easier capture of the materials.